About Carbon Black

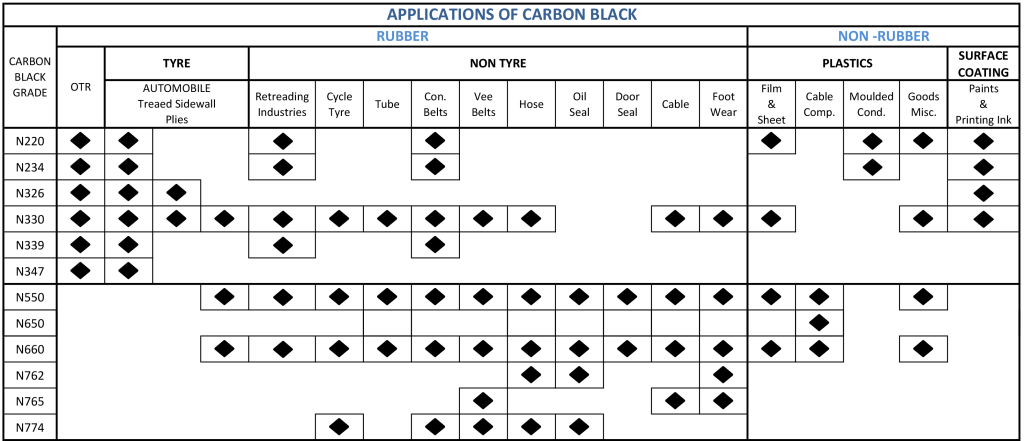

Carbon Black is produced by Thermal Cracking of highly aromatic oils. The basic principle involves the cracking or “pyrolysis” of natural gas or liquid hydrocarbon in a limited supply of air to form Carbon Black particles. These particles after a number of further stages of formation and treatment take the final Pellet form. Carbon Black has wide applications in the manufacturing of Tyres, Tubes, Rubber goods, Paints, Printing Inks and items made from Plastics.

In the application of rubber goods the “reinforcing” ability of Carbon Black is the prime factor guided by its Surface Area, Structure and Surface activity. Further, its unique morphological characteristic has enabled its use in diverse application areas. Depending on Surface area and Structure, various grades have been developed. The grades are available in various kinds of Packaging depending upon the requirements of the customers. The Packaging are:

- 25 Kg Paper Bag

- 1000 Kg Flexible Intermediate Bulk Container (FIBC)

- 500 Kg Flexible Intermediate Bulk Container (FIBC)

Application

Our Products

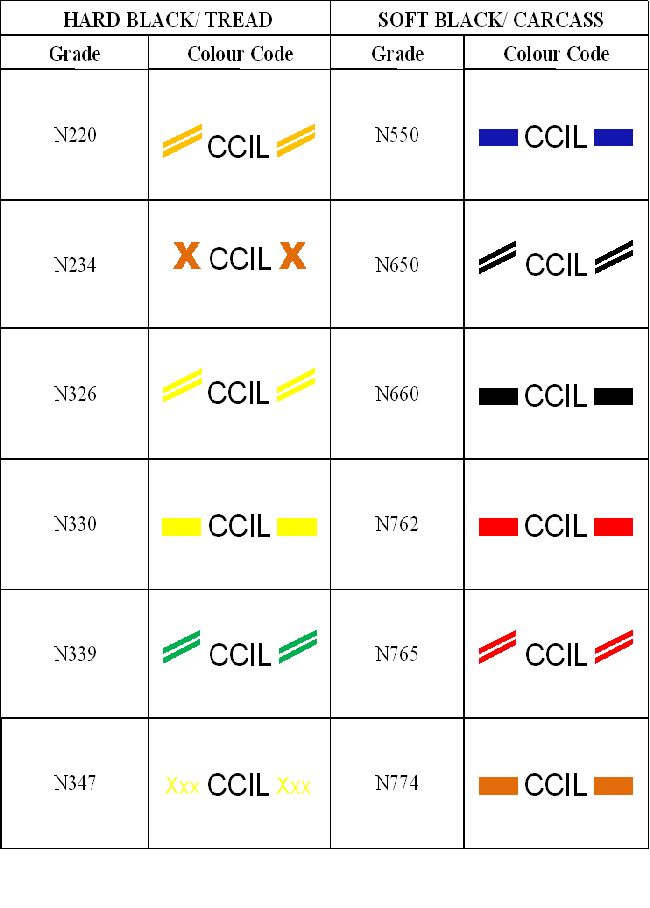

Depending upon the Surface Area, Structure, Tint Strength, Pour Density, and Rubber Properties of the pellets formed, various grades of Carbon Black have been developed.

Quality Testing

- CCIL has a well equipped laboratory for characterization of carbon black grades.

- Surface area of carbon black grades measured by iodine absorption, a method for quick assessment during in process quality control as well as for ensuring packed material before shipment.

- Structural anisometry of carbon black grades measured by sophisticated absorptometerc -having arrangement of precise control over temperature of absorption chamber and DBP oil fitted with software. Primary structure measured at specified intervals after crushing carbon black in compressed DBP pressd.

- Tint strength of carbon black grades measured at least once in every production run through tint testing apparatus by measuring percent transmission using ERICHSEN Tint Tester – 527.

- Hardness of carbon black pellets is extensively checked during in process quality control as well as before shipment of packed material using Individual Pellet Hardness Tester of HITEC – Luxembourg.

- Rubber properties of carbon black grades are studied on regular basis after mixing in two roll mill.

- Curing characteristics are checked in Monsanto R-100 Rheometer.

- Prior to curing of compounded rubber samples in electrically heated semiautomatic curing press.

- Physical properties are measured in the ZWICK Universal Testing Machine.

- Special properties eg. Abrasion Index of Carbon Black grades are measured in DIN Abrader.

- Whenever required and facility for checking Die Swell and Extrusion Shrinkage using lab size extruder also having in CCIL.